- Product details

- Product profile

1. Introduction to the equipment

The new TTO thermal transfer paging machine is based on the successful application experience of both the "standard TTO thermal transfer paging machine" and the "simple TTO thermal transfer paging machine" in the veterinary medicine, pesticide, seed and traditional Chinese medicine industries. , At the same time, it integrates various user feedback information and is specially developed to meet the needs of new industries. It can better satisfy: "ultra-thin", "ultra-soft", "ultra-static" and other three super problems, as well as new types of packaging bags such as special-shaped structure, "M-shaped" multi-layer bags, zipper-sealed bags and "easy-tear" bags The demand for paging feeding and heat transfer printing. Whether it is speed and stability, or the convenience of operation and maintenance, it has an unprecedented height, especially the problem of long-term manual coding of packaging bags in the bakery food industry!

2. Equipment parameters

1. Dimensions: length*width*height=2260*763*820mm (note: belt width 400mm, length 1200mm,)

2. Net weight: about 200KG

3. Power supply: 220VAC

4. Total power: about 600KW (including negative pressure adsorption), about 300W (not including negative pressure adsorption), only paging machine

5. Belt running speed: 0-50m/min

6. Control mode: PLC+touch screen; speed governor and speed regulating motor

6. Air source: 0.3-0.6MPa without water (not needed for paging machine, according to whether the printer needs to be configured)

8. Paging principle: friction type, bottom discharge

9. Adapt to product types: various packaging bags

10. Adapt to product specifications: length * width * thickness = (60-300) * (60-380) * (0.1-3) mm

11. Effective print width adjustment range: 300mm (handle adjustment)

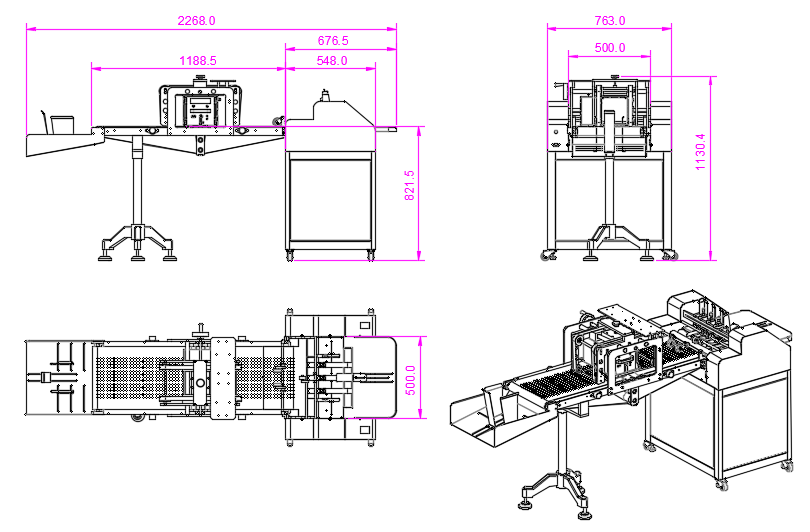

3. Reference size and sample drawing of equipment appearance

Four, design advantages or improvements

1. It can be equipped with negative pressure adsorption function: to ensure that the product delivery process does not shift, the printing position is more accurate, and it is better for the material "light and thin" packaging bags

2. Designed in the form of "pipeline": it is convenient to install "code-spraying system" or "visual inspection system", "labeling system", etc., to realize the module can be highly integrated and convenient, which solves the problem of dispersing various processes in different models Completion of the drawbacks, saving labor costs and plant area issues

3. The paging system discards the "traditional friction type": select the "static friction" paging principle of our new invention patent + the arrangement of 3 paging friction belts; it can be adapted to various sizes and various materials and thickness unevenness and belts to the greatest extent Sealed zipper packaging bag, and it is not easy to cause scratches on the surface of the product

4. Fully open modular system design: It can easily realize "one machine with multiple channels" and "one machine with multiple heat transfer machines" to double the production capacity and save labor to the greatest extent; it is convenient to replace various paging modules according to different products

5. The special friction belt is wear-resistant and does not drop powder (dregs); it is very beneficial to the subsequent printing effect and protects the print head of the thermal transfer machine

6. Adopt dual DC speed-adjusting motors: independent speed regulation of the paging and conveying system, which is convenient for speed adjustment and facilitates the separation of products of various sizes; the DC motor has large torque, smooth bag walking, low noise and low power consumption

附件:配置清單

| 額定功率(kw) | 普通噴印1.0KW | |

| 尺寸(L*W*H) | 見具體機(jī)型參數(shù) | |

| 噪音(分貝) | 50-55dB | |

| 重量(噸) | 約200KG | |

| 項(xiàng)目 | 名稱 | 規(guī)格與廠家 |

| 設(shè)備配置 | 調(diào)速器及調(diào)速電機(jī) | TWT |

| PLC | 西門子 | |

| 觸摸屏 | 威倫 | |

| 低壓電氣開關(guān) | 正泰 | |

| 分頁皮帶 | 銳越嘉 | |

| 風(fēng)機(jī) | 全風(fēng)/雨田 | |